product details

Master Precision with the 2Create Dental 3D Printer

Experience the fusion of accuracy and versatility with the 2Create metal dental 3D printer. Designed for dental applications and research settings, this printer enables precise creation of custom dental prosthetics and detailed research models. Its user-friendly interface and flexible material selection provide an innovative solution for your projects.

Unmatched precision in printing enables the creation of detailed dental prosthetics and complex research models, elevating the standard of output.

Explore a broad spectrum of materials from aluminum to titanium, opening doors to diverse project requirements and experimental pursuits.

Cost-effectiveness paired with high-quality production makes it a preferred choice for both dental labs and research institutions.

Rapid material change feature accelerates the workflow, significantly reducing the downtime and boosting the overall productivity of projects.

These Advantages Await You When Working with 2onelab

Fast Material Change

Change your 3D printing metal powder within 20 minutes.

Easy to use

The dental 3D printer is easy to use, even for beginners.

Instant Printing

Ready to print in below 5 minutes (from 21% oxygen to below 1%)

Short Production Times

Faster turnaround times while delivering superior quality products.

Versatility

Print with a variety of metals including titanium, steel, and aluminum.

Made in Germany

Made in Germany with optimal support for the best quality.

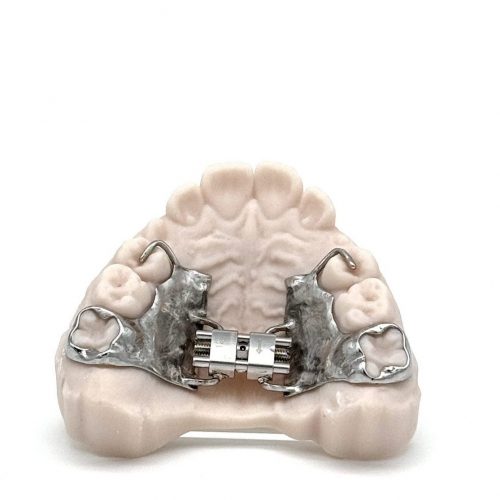

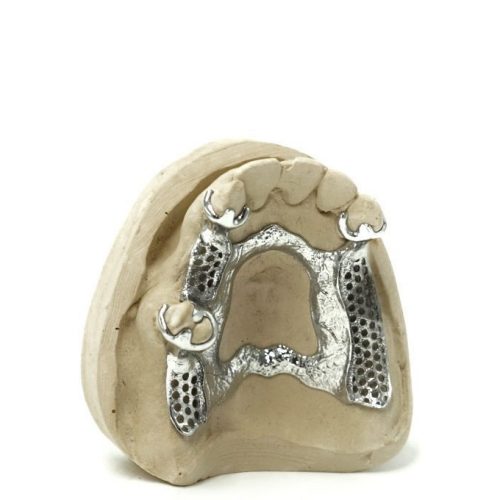

3D printed dental models

what our customers say

The 2Create laser sintering system impressed us

As a young company, we rely on punctual deliveries and the highest quality. The 2Create laser sintering system impressed us last year by combining speed, precision, and reliability.

Marcus Kalb

Prinoa/Germany

2onelab has provided us with such superior support …

… while working on an innovative path forward for SLS in orthodontics. We are deeply committed to technology, and found a partner who can more than keep up in our pursuit to lead the industry forward. Compact machine, easy to setup and use, with consistently high product quality – we couldn’t ask for more!

Christian Saurman

NEOlab/USA

Reliable Technology and Outstanding Support

At Ewert Zahntechnik in Soest, we chose the laser melting machine from 2onelab – and we haven’t regretted it for a single moment. From day one, the machine has run smoothly in our workflow. The results are outstanding, the operation is intuitive, and the support is truly excellent. A clear recommendation!

Peter Ewert

Ewert Zahntechnik/Germany

Over a year, the company tested various manufacturers and machines, ultimately choosing 2onelab …

… due to their strong focus on dental equipment and their provision of both hardware (2Create) and software (2Build). After more than half a year of collaboration, they highly praise 2onelab for their swift and effective support, which contrasts with the slower response times experienced with larger competitors during their machine purchase tests.

Stefan Fenske

Medicalformers/Germany

The 2Create laser sintering system impressed us

As a young company, we rely on punctual deliveries and the highest quality. The 2Create laser sintering system impressed us last year by combining speed, precision, and reliability.

Marcus Kalb

Prinoa/Germany

2onelab has provided us with such superior support …

… while working on an innovative path forward for SLS in orthodontics. We are deeply committed to technology, and found a partner who can more than keep up in our pursuit to lead the industry forward. Compact machine, easy to setup and use, with consistently high product quality – we couldn’t ask for more!

Christian Saurman

NEOlab/USA

Reliable Technology and Outstanding Support

At Ewert Zahntechnik in Soest, we chose the laser melting machine from 2onelab – and we haven’t regretted it for a single moment. From day one, the machine has run smoothly in our workflow. The results are outstanding, the operation is intuitive, and the support is truly excellent. A clear recommendation!

Peter Ewert

Ewert Zahntechnik/Germany

Over a year, the company tested various manufacturers and machines, ultimately choosing 2onelab …

… due to their strong focus on dental equipment and their provision of both hardware (2Create) and software (2Build). After more than half a year of collaboration, they highly praise 2onelab for their swift and effective support, which contrasts with the slower response times experienced with larger competitors during their machine purchase tests.

Stefan Fenske

Medicalformers/Germany

Our digital 3D printing ecosystem

2Build: In-house developed CAM Software

- Nesting: High-speed nesting saves valuable post-processing time

- Labeling: Advanced labeling for easy identification of all parts

- Support Generation: Sophisticated, fully automated support generation

2Connect: Integrated Website Solution

- Marketplace for Printing Strategies: Library for printing parameters and strategies

- Organizing and Tracking 3D Printing Projects: Important informaton at a glance

- Optimized for Service Excellence: Central hub for all relevant data regarding your metal 3D printers

CAM software

2Create: Interface Software

The 2Create’s software makes setup and use easy. Manage the whole printer using just three tabs. The clear software layout and step-by-step guides make complex tasks simple, helping you learn fast and become a system expert quickly. If you run into issues, the 2onelab team can help remotely.

Simple Setup and Powder Changing

The 2Create is designed for quick job change – finish one job and set up the next within 15 minutes. Switching from CoCr to Titanium? No problem. Changing from reactive to non-reactive powders is a breeze, taking less than 20 minutes. Efficiency is at the core of 2Create’s design.

materials

Cobald-based alloy

CoCr

Aluminum

AlSi10Mg

Iron-based alloy

316L, 17-4 PH

Nickel-based alloy

625, 718

Copper-based alloy

Bronce

Titanium

Ti6Al4V

FaQ

2Create - Dental 3D Printer for Metal

The Process and 3D Printing

What makes the 2Create Dental 3D Printer ideal for dental and R&D use?

The 2Create is tailored for dental applications and research environments. It offers high precision, efficient powder handling, and an open software architecture — all in a compact and cost-effective system.

What are the benefits of the orbiting coater?

1. It speeds up the coating process. The blade only has to cross the build platform once, then returns after continuing around in a clockwise direction. Laser printing can then immediately start while it is still circling back to its initial position.

2. Powder “overflow” can be easily stopped when necessary. This results in more efficient powder use.

3. This design simplifies the overall process of metal 3D printing, making the dental 3D printer more efficient without requiring complex mechanical systems.

What kind of coating blade does the 2Create use?

We use a rubber lip. It is reliable and ensures good-quality, uniform coating.

Can the system also be used with argon instead of nitrogen?

Yes. You simply supply it with argon instead of nitrogen.

What kind of cooling system does the laser have, and how long do the diodes last?

The laser has air cooling. The diodes have a service life of over 200,000 hours.

Where does the laser come from?

We always use high-quality laser sources from IPG, a leading company in laser technology.

Is the entire production outsourced, or do you carry out certain steps in-house?

We are proud to manufacture almost all components of our 3D dental printing systems ourselves at our production site in Darmstadt, Germany. This high level of in-house production guarantees outstanding quality, reliability, and true “Made in Germany” craftsmanship.

What optical system are you using?

We use only high-end German brands in our printers, such as Raylase for the scanhead and Jenoptik for the optical lenses.

The laser has an optical power of 250W. Are other output powers available if needed?

Yes, we can install a 400W laser in the system.

Which file formats are currently supported?

STL, 3MF, OBJ, IGES, and STEP.

In what format is data sent to the system? Is it an open format?

Data transmission occurs in a version of G-code, the standard programming language used to control automated CNC machine tools. Unlike other manufacturers, we offer an open format, making our dental 3D printer especially attractive for universities and research institutions.

What are the smallest structures that can be printed?

With a 40μm spot, the melt pool is always larger than the spot itself. Diameters of up to 60-80μm can be achieved by adjusting the scanning speed.

How often does the rubber lip need to be replaced?

We recommend replacing the rubber lip after every two or three print runs, or more often if needed. The lips cost only a few euros each.

How much shielding gas does the system require?

The system consumes approximately 0.2m³/h during operation. A larger quantity may be required for flooding the system at startup.

What grade should the nitrogen be?

For optimal results, we recommend using nitrogen 5.0 (DIN EN ISO 14175, 99.999% purity).

What maintenance does the laser require?

The laser and all optical components require no maintenance.

How long does it take to change the powder?

A skilled user can change it in under 20 minutes. The process is very easy and straightforward.

Which metals can the 2Create Dental 3D Printer use?

The 2Create Dental 3D Printer supports all metals validated for the 2onelab platform, including:

– Cobalt-chrome

– Titanium

– Stainless steel

– Tool steel

– Nickel-based superalloys

– Aluminum

Which powder grain sizes can be used?

The grain size typically ranges from 15 μm to 45 μm. Finer powders can be used, but the normal layer thickness is 30μm. There is a direct relationship between the smallest powder grain size and the layer thickness.

What requirements must powder meet to be suitable for use?

The powder of the dental 3D printer must have an appropriate grain size, meaning small enough to build layers of the selected thickness (e.g., 30μm). If the powder is too fine, there is a tendency for soot to form, and the results may be less accurate. Spherical powder grains are preferable. High-quality powder of this kind is produced by gas or water atomization.

Does powder age? Can it be reused?

Unused powder ages during the printing process, and residue particles can contaminate the powder bed. To maintain high powder quality, it is recommended to sieve the leftover powder after each print using the 2Sieve.

We are planning to offer appropriate solutions for this in the near future. If high density is important in the printed part, old powder should be ‘freshened’ by mixing it with new powder in a one-to-three ratio.

What are reactive materials?

Reactive materials include titanium and aluminum. They are characterized by low activation energy, among other properties. Special care must be taken with the nanoparticle residue produced during the laser printing process, as it readily reacts with oxygen in the air in an exothermic reaction (it gets hot and burns!).

Related

products

2Create Plus

Compact Metal 3D Printer for Maximized Output

The 2Create Plus enhances productivity with a larger platform for expansive production needs. Elevate output for dental, medical and industrial applications.

2Clean

Cyclonic Precision in Powder Recovery

2Clean, equipped with an integrated cyclone separator, is your go-to solution for reclaiming non-reactive materials like CoCr or stainless steel.

2Sieve

Ultrasonic Sieving Excellence

2Sieve, a unique compact ultrasonic sieve, cleans used powder making it reusable. Its ability to operate under argon allows safe sieving of reactive materials like titanium.

Furnaces

3D Printing Furnaces

The HTS-2/Metal Glow-120+ and Glow Cube-200+ optimize thermal post-processing, ensuring outstanding material properties.

Polisher

3D Print Polishing Machines

The optimal polishing solutions for the dental sector, specifically for CoCr and Titanium. Achieve a perfect shine with minimal effort.

2N2

Industrial Nitrogen Generator

Our Nitrogen Generator 2N2 is a standalone solution requiring only mains power, equipped with an in-built compressor to extract nitrogen from air via a membrane.

2Create Plus

Compact Metal 3D Printer for Maximized Output

The 2Create Plus enhances productivity with a larger platform for expansive production needs. Elevate output for dental, medical and industrial applications.

2Clean

Cyclonic Precision in Powder Recovery

2Clean, equipped with an integrated cyclone separator, is your go-to solution for reclaiming non-reactive materials like CoCr or stainless steel.

2Sieve

Ultrasonic Sieving Excellence

2Sieve, a unique compact ultrasonic sieve, cleans used powder making it reusable. Its ability to operate under argon allows safe sieving of reactive materials like titanium.

explore

markets

Dental

Precise 3D Printing for Dental Applications

Custom-made partial frames, crowns, and ortho bands in CoCr & Titanium. Cost- and time-efficient fabrication.

Science

Advancing Innovation through Additive Manufacturing

Open AM hardware, CAM Software and great flexibility: We are the ideal partner for your project.