Metal 3D printing opens up new possibilities across numerous industries: complex geometries, customized parts, and materials with special properties can be produced in this way. To fully harness the potential of this technology, a solid understanding of the process is essential.

Below are eight practical tips to help improve process reliability and part quality in metal 3D printing.

1. Proper Storage of Metal Powder

Metal powder is hygroscopic, meaning it easily absorbs moisture from the air.

Tip: Store the powder in airtight, dry containers, such as sealed boxes or climate-controlled cabinets. Check regularly for any moisture.

Benefit: Better flow, a more consistent melting process, and cleaner surfaces.

2. Ensure Powder Quality & Purity

Foreign particles or mixing different materials, can affect quality.

Tip: Keep powders strictly separated by material and use dedicated tools for each type. Keep the workspace clean and perform regular quality checks.

Benefit: Uniform density, reproducible strength, and consistently high part quality.

3. Manage Protective Gas & Build Chamber

The right protective gas prevents oxidation, and a clean build chamber ensures stable results.

Tip: Choose the appropriate protective gas (e.g., argon for titanium and aluminum) and clean the build chamber after each print. Ensure a steady gas flow.

Benefit: Ensures strong adhesion, uniform density, and high-quality surfaces.

4. Choose the Right Build Platform

The build platform affects adhesion and stress relief during cooling. Using the wrong material can lead to warping or poor adhesion.

Tip:

- Titanium: Print only on a titanium build platform

- Aluminum: Print only on an aluminum build platform

- Other Metals: Stainless steel platforms are versatile, offering good adhesion and high temperature resistance

Benefit: Stable parts and reliable print results without cracking.

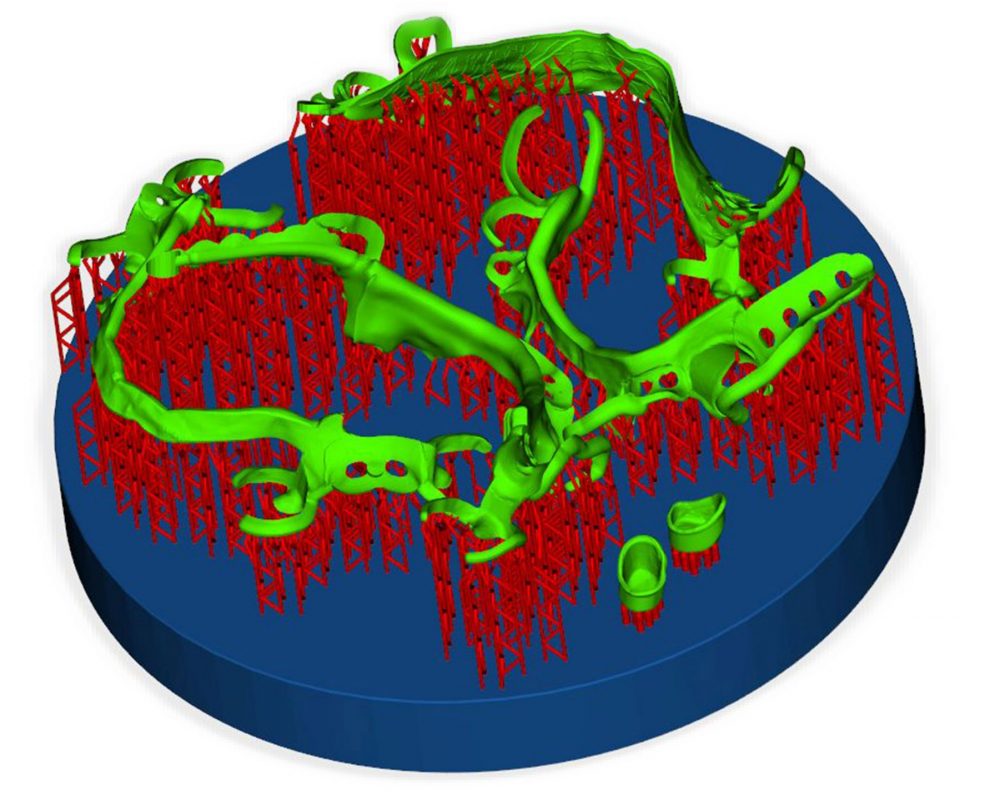

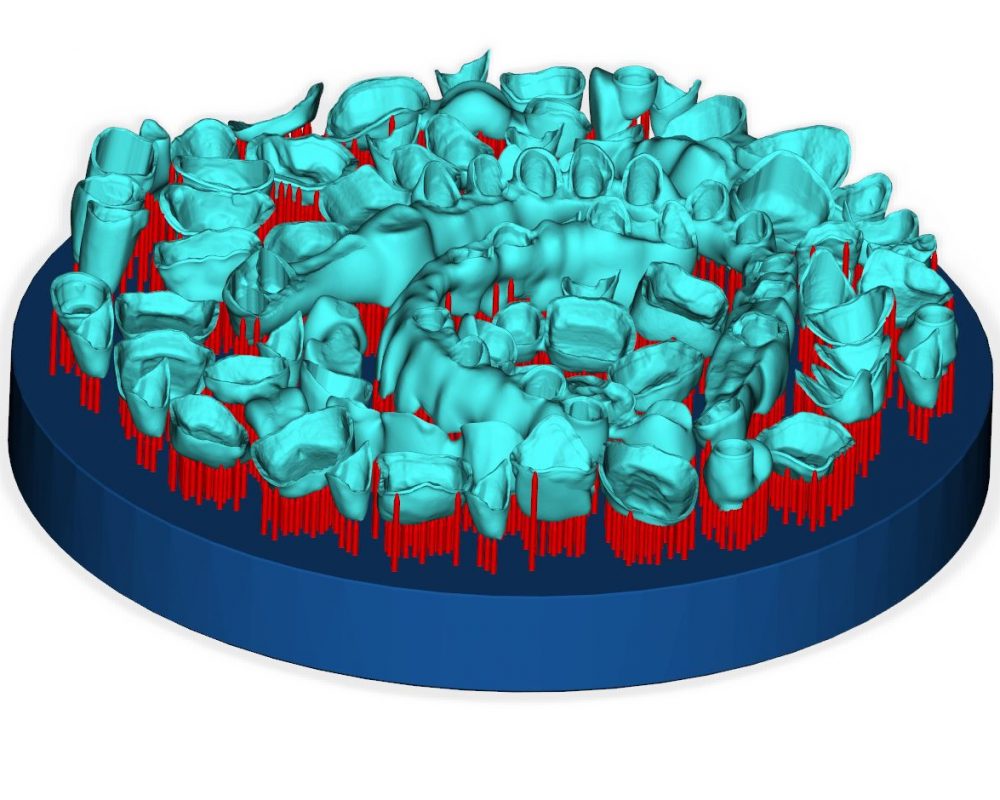

5. Use Support Structures Cleverly

Support structures (lattice and rod supports) stabilize parts and effectively conduct heat away.

Tip: Place supports strategically so they provide stability but can be easily removed after printing.

Benefit: Stable parts, high-quality surfaces, and easy post-processing.

Which Supports to Use?

- Lattice Supports (lattice structures) are ideal for large, complex parts.

- Rod Supports (rod structures) are better for small or delicate areas.

6. Optimize Part Orientation

The orientation of a part affects heat dissipation, stability, and post-processing effort.

Tip: Orient parts so that stresses are evenly distributed and as few supports as possible are needed.

Benefit: Stable parts, high-quality surfaces, and easy post-processing.

7. Adjust Printing Parameters

The right settings for laser power, scan speed, track spacing, and layer thickness ensure the material melts evenly.

Tip: Regularly check parameters and adjust them for each material. Tools like the 2Connect Web App provide verified printing strategies for different metals.

Benefit: Uniform parts, reliable strength, and reproducible quality.

8. Stress Relief Annealing

In metal 3D printing, internal stresses can develop due to uneven cooling, which may cause warping or cracks.

Tip: Stress relief annealing reduces these stresses evenly—especially important for large, complex, or delicate parts.

Benefit: Stable parts with high dimensional accuracy and long service life.

Conclusion

With careful powder handling, clean processes, and optimally adjusted parameters, high-quality parts can be reliably produced in metal 3D printing.

By following these best practices, manufacturers can ensure part stability, consistent quality, and efficient production.