Five reasons why dental 3D printing is becoming the standard in prosthetics – and why 2onelab delivers a workflow that really works.

Key Points in Brief:

- Dental 3D printing is now core infrastructure for modern labs.

- Faster, predictable workflows reduce manual steps and remakes.

- Consistent quality and competitiveness improve margins and resilience.

Anyone Who Does Not Adopt Dental 3D Printing Now Will Be Left Behind

The most underestimated trend for 2026 is not the growth of digital tools.

What matters is how seamlessly these technologies have already become part of everyday laboratory routines.

Dental 3D printing is no longer a pilot project. It is a core function of modern dental technology.

Today, 3D printing is not “innovation.” It is infrastructure.

This shifts the key question:

No longer whether digitalization will take place, but how reliably the digital workflow actually runs in daily laboratory operations.

And it is clear: anyone who does not invest in dental 3D printing now will be left behind.

5 Reasons Dental 3D Printing Transforms Labs

1) Turnaround Times Cut in Half: Dental 3D Printing Makes Turnaround Predictable

In prosthetics, turnaround times increasingly determine competitiveness. Where digital manufacturing is consistently integrated, not only are times reduced – they become predictable.

- Fewer manual intermediate steps

- Fewer handovers

- Fewer external dependencies

The result is a stable process for prosthetic components that produces faster and delivers more reliably – even for demanding cases and changing order mixes.

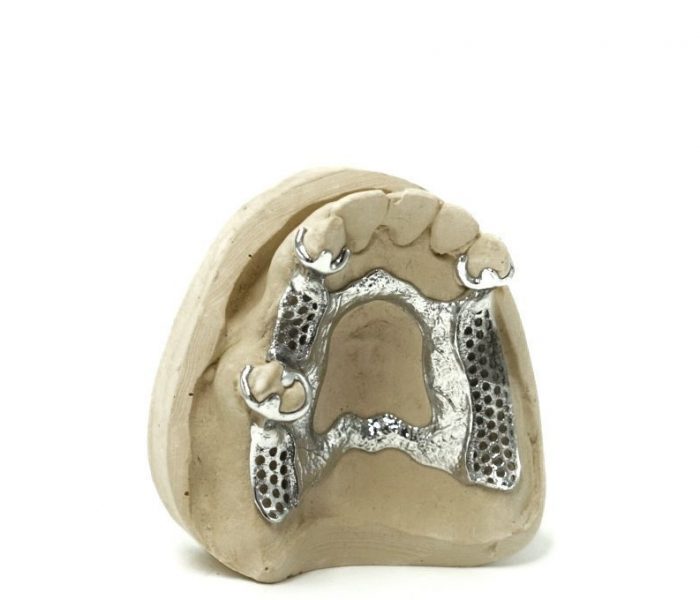

2) More Control Over Design & Materials: Reproducibility Instead of Compromise

With an integrated digital workflow, control returns to the dental laboratory:

- Design, parameters and material selection follow a reproducible process chain instead of relying on “best effort” and individual readjustments.

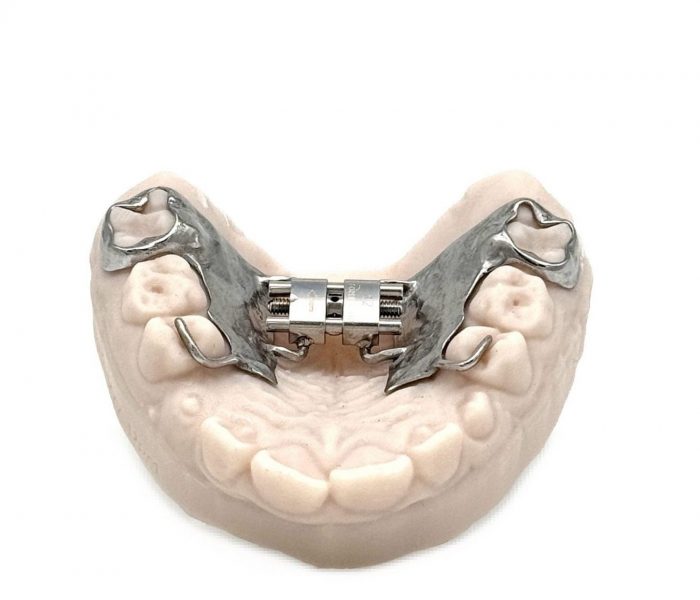

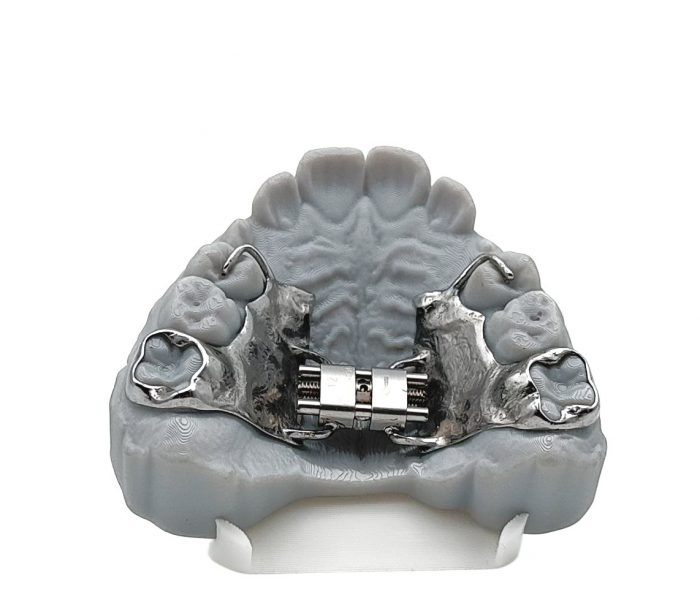

Especially in metal-based prosthetics, this means consistent results, less variation, clearly defined quality standards – and less dependence on improvised workarounds.

3) Better Margins, Fewer Remakes: Profitability Through Process Stability

Margins in the dental laboratory are not created through higher complexity, but through stable processes:

- Less rework

- Fewer remakes

- Less scrap

And therefore more productive time in design, manufacturing and finishing.

When dental 3D printing is operated as infrastructure, quality is achieved systematically, not“produced.”

This increases profitability and service levels for practices and clinics.

4) Autonomy & Resilience: Independence in Manufacturing and Delivery Capability

Laboratories that integrated digital manufacturing early and consistently are now more autonomous and resilient:

- Less dependence on external manufacturing steps

- More stable capacity planning

- Better responsiveness under time pressure or short-term changes

Resilience is not a “nice-to-have” in 2026. It is a tangible competitive advantage – especially in prosthetics, where time windows are tight and requirements are high.

5) Competitiveness: The Industry Is Moving – and It Is Not Waiting

Those who delay adoption do not only lose efficiency – they lose competitiveness.

The market increasingly expects:

- Short turnaround times

- Reproducible quality

- A digital process chain independent of individuals

In 2026, the question is no longer whether digitalization will happen.

The question is: how good is the digital workflow really?

And anyone who does not adopt dental 3D printing now will be left behind.

2onelab’s Digital Workflow for Dental Laboratories

Why 2onelab: One Continuous Workflow – No Trial and Error

Many digitalization approaches fail not because of the technology, but because of everyday reality:

- Isolated solutions

- Interface problems

- Manual workarounds

- Permanent readjustment

In the end, this creates a setup that requires attention while still leaving key questions unanswered.

2onelab stands for a different approach: a continuous, practice-oriented digital workflow for metal-based manufacturing in the dental laboratory – designed to function in daily operations:

Stable. Repeatable. Scalable.

The objective is clear:

No tinkering, no “assembled” tool landscapes, no constant readjustment – but infrastructure that runs.

Conclusion – Dental 3D Printing as Infrastructure

If dental 3D printing is infrastructure– and if turnaround, process control, remake rates and margins measurably benefit from it – then one question remains:

Why is the new digital dental workflow not yet being adopted consistently?

Anyone who answers this question now is not only deciding on an investment, but on the position of the dental laboratory in prosthetic manufacturing in the years to come.