3D printed suppressors – where engineering meets precision. Learn how a suppressor reduces the sound of a gunshot through intelligent design, the right choice of materials, and 3D printing.

Metal 3D-printers such as the 2Create and 2Create Plus produce complex, highly durable, and heat-resistant components.

Key Points in Brief:

What is a 3D Printed Suppressor?

It is a 3D printed component designed to reduce the noise of a gunshot.

How Does It Work?

It redirects and slows the gases exiting the suppressor, reducing pressure peaks and spreading out the sound.

What are Suitable Materials?

Titanium is lightweight and strong, while nickel alloys are highly heat-resistant – both are suitable for complex shapes that are only possible with 3D printing.

What Are the Advantages of 2Create/2CreatePlus?

Compact build volume, powerful laser, fast material change, and direct production from digital models.

3D Printed Suppressors: Technology & Function

3D printed suppressors are currently a widely discussed topic. But how does a suppressor actually work? In short: it turns a brutal, short pressure spike into a longer, much gentler gas release.

During a shot, high pressures and temperatures build up inside the barrel; the gas “queues” behind the projectile. When the bullet leaves the barrel, the gas escapes suddenly – the steep pressure front is what we hear as the gunshot.

Internal Architecture & Gas Flow

A suppressor works by giving the gases volume, forcing them on detours, breaking up the flow into turbulence, and stretching the pressure curve over time.

Physically, this results in: lower peak pressures, a shifted frequency spectrum, and significantly reduced sound levels.

Design-wise, this appears as a housing in front of the muzzle with sophisticated internal architecture: expansion chambers, redirection zones, varying cross-sections, and surfaces that slow the flow and create turbulence.

Turbulence & Heat Conversion

The gas expands into larger volumes, loses pressure and speed, and is repeatedly redirected and split. Turbulence and shear convert part of the acoustic energy into heat.

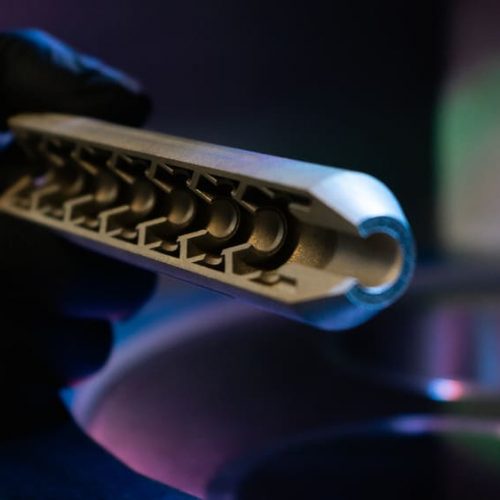

3D printed silencer (titanium) from the front (left) and the back (right) – Printed with 2Create

This is exactly where metal 3D printing shows its strengths: the internal geometry of 3D printed suppressors can be freely designed according to flow physics and thermal requirements – something not possible with drills or milling.

Titanium & Nickel-Based Superalloys: Materials In Focus

Certain metals, such as titanium and Inconel, are particularly suitable for 3D printed suppressors:

Titanium Alloys (E.g., Ti-6Al-4V)

Titanium stands out for lightweight construction, high strength, and corrosion resistance – ideal for parts with complex internal geometries that also need to be durable.

Key Features:

– Density & Lightweight – density approx. 4.4 g/cm³, roughly half as heavy as typical nickel alloys.

– Strength & Corrosion – high tensile strength even achievable with LPBF processes, very good corrosion resistance for varying conditions.

– Limits – lower temperature resistance, reduced durability under very high thermal loads.

Nickel-Based Superalloys (E.g., Inconel 718)

Nickel-based superalloys such as Inconel 718 offer exceptional heat resistance and stability, even under repeated thermal stress.

Key Features:

– Density & “Armor Factor” – density approx. 8.2 g/cm³, heavier than titanium, but very robust.

– High-Temperature Strength – high strength and creep resistance even under repeated heating/cooling cycles and local hot spots.

Thanks to these properties, 3D printed suppressors can be produced efficiently while being durable and high-performing.

Conclusion: 3D Printed Suppressors

With metal 3D printing, 3D printed suppressors with complex internal geometries, optimized flow, and carefully selected materials can be manufactured efficiently and reproduced directly from digital models.

Efficient Production of Complex Metal Parts

The 2Create Plus (3D printer suppressor), with its relatively large build volume and compact footprint, is the ideal system for producing highly complex components such as suppressors.

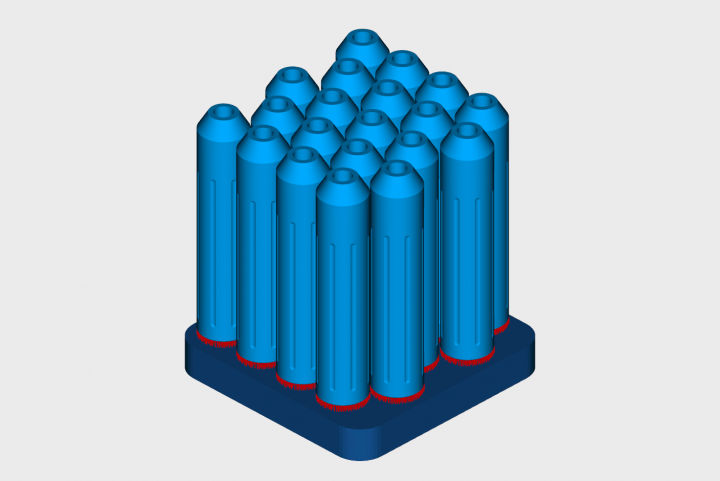

Titanium suppressors (STL-file) on build platform (2Build CAM)

Titanium suppressors (STL-file) on build platform (2Build CAM)

Key Features

Build Volume

– Square build area 150 × 150 mm – optimal for producing multiple parts with complex internal structures simultaneously.

Laser

– 400 W fiber laser – sufficient power for titanium and nickel-based superalloys with high detail fidelity.

Machine Footprint

– Machine dimensions approx. 720 × 860 × 1790 mm, – weight ~450 kg – full industrial performance in a small footprint.

Process Gas & Peripherals

– Operates under nitrogen or argon – ideal for reactive titanium.

– Oxygen content in the build chamber reduced from 21% to <1% in under 2.5 minutes – quickly ready for printing..

– Powder change in approximately 20 minutes – perfect for switching between titanium and nickel-based alloys.

Contact us for more information!

FAQ: 3D Printed Suppressors

Can You 3D Print a Silencer or Suppressor?

Yes, metal 3D printing can be used to produce suppressor components. Material choice, design, and manufacturing technology are critical to ensure stability, heat resistance, and function.

How Do 3D Printed Suppressors Work?

They reduce the sound of a gunshot by directing the escaping gases, while expansion chambers and complex internal geometries lower pressure peaks and convert some of the acoustic energy into heat.

Which Metals Are Suitable for 3D Printed Suppressors?

Titanium alloys and nickel-based superalloys are ideal. They combine strength, heat resistance, and the ability to produce complex internal geometries.

How Durable Are 3D Printed Suppressors?

Durability depends on the metal used: titanium alloys are lightweight and strong, while nickel-based superalloys withstand high heat. Correctly produced parts resist repeated thermal and mechanical stress.

Are 3D Printed Suppressors Legal?

Legality varies by country. In many places, suppressors require permits or are prohibited. Always check local regulations before manufacturing or owning one.

What Are the Advantages of the 2Create and 2Create Plus for Production?

The 2Create and 2Create Plus (3D printer suppressors) allows efficient production of complex metal components. Benefits include a compact footprint, high laser power, fast material change, and precise control of process conditions.

Further links:

Author: Markus Wolf

Passionate about 3D printing, while being

CTO and Co-Founder of 2onelab.