Metal 3D printing is gaining importance worldwide, enabling the precise and efficient production of complex components in dental technology, medical devices, and industrial applications.

Below, we explain how metal 3D printer costs are made up of fixed and variable expenses — and why the machine price alone provides only a limited picture of the total investment.

Key Points in Brief:

- Advantages of Metal 3D Printing: Efficient manufacturing, high precision, and flexible production of complex components.

- Metal 3D Printer Costs ≠ Price: The purchase price alone is not enough – operational costs, materials, maintenance, infrastructure, and training must also be considered.

- Investment Decisions: A thorough cost analysis ensures economically sound investments.

Metal 3D Printer Costs vs. Price

Metal 3D printing technology optimizes processes, making production faster, more flexible, and cost-efficient. This is why it’s important to look beyond the purchase price of a metal 3D printer and consider both fixed and variable costs before making an investment decision.

How Are the Costs Composed?

The costs of metal 3D printers are made up of fixed and variable costs.

Fixed Costs

- Purchase price of the machine

- Optional software and necessary equipment

- Shipping and, if necessary installation

Variable Costs

- Warranty and maintenance expenses

- Downtime costs

- Consumables

- Powder usage efficiency

- Employee training / learning curve (time)

Fixed Costs

Fixed costs are independent of production volume and form the base investment for a metal 3D printer.

- They include the machine purchase price, software, and necessary equipment—especially for post-processing—plus shipping and, if applicable, installation.

- These costs are usually one-time expenses and serve as the foundation for planning the total investment.

Variable Costs

Variable costs depend directly on machine usage and can significantly impact the actual metal 3D printer expenses.

- They include warranty and maintenance costs, regular calibration, cleaning, and complex powder handling.

- Downtime generates additional costs due to delayed orders, dissatisfied customers, and lost revenue.

- Powder efficiency also plays a role, as efficient powder usage saves material, time, and labor.

Finally, employee training and the learning curve are important factors: complex systems require skilled operators and onboarding time—often an underestimated but relevant cost component.

Advantages with 2onelab

– All-in-One Solution: Metal 3D Printers (2Create/2Create Plus) + Software (2Build CAM) + optional equipment

– Warranty & Maintenance

– 24h/7 Support for questions or issues

– Employee Training: Learn software & workflow in just 2 days

– Ready-to-Print Setup: Easy operation, short production times

Learn in the video how our partner Prinoa uses the 2Create metal 3D printer and 2Build to complete orders within 24 hours.

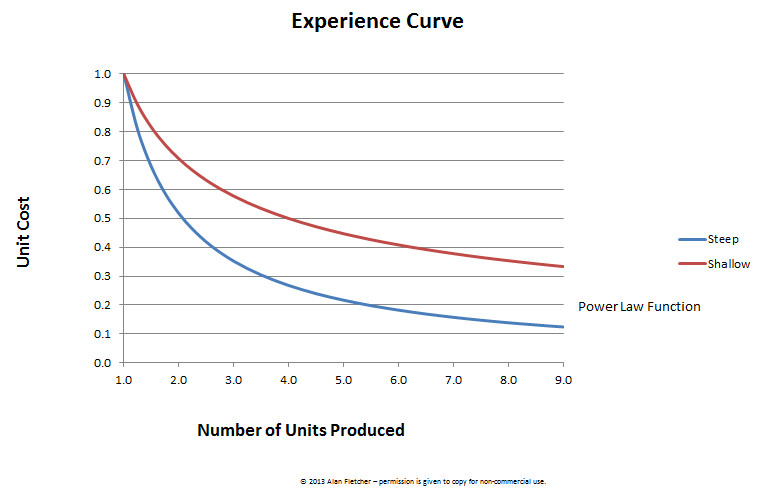

Experience Curve (Learning Effects)

The Importance of the Experience Curve – Experience Reduces Costs

An often underestimated indirect cost factor in metal 3D printing is the learning effect.

It directly affects the time required for order processing. The basic idea: the more a company produces, the cheaper each subsequent unit becomes, as experience is gained.

This is reflected in the following points:

- 1. Faster, more skilled employees: Results in fewer mistakes, shorter processing times → lower unit costs.

- 2. Optimized processes: Results in fewer mistakes, shorter processing times → lower unit costs.

- 3. Targeted machine operation, less scrap: Fewer defective products → reduced material waste → lower costs.

- 4. Automation through learning: Experience leads to automation → focus on value-adding tasks.

Conclusion – Metal 3D Printer Costs

Metal 3D printer costs go far beyond the machine price alone: fixed and variable costs, maintenance, material usage, and training all significantly impact the actual investment.

Considering these factors enables more efficient processes, lower unit costs, and economically sound use of metal 3D printing.

The complete Digital Metal 3D Printing Ecosystem by 2onelab

Metal 3D Printers

CAM Software & Web Monitoring App

Equipment

Contact us for more information!

FAQ – Metal 3D Printer Costs

What Is the Difference Between Metal 3D Printer Price and Costs?

The price refers to the machine’s purchase cost only. Costs additionally include maintenance, consumables, powder efficiency, downtime, and training.

Only by considering all these factors can the actual investment be realistically assessed.

What Are the Fixed Costs for a Metal 3D Printer?

Fixed costs are independent of production volume and include the machine price, software, equipment, shipping, and installation. They form the basis for investment planning.

What Variable Costs Should I Plan For?

Variable costs depend on usage and include maintenance, warranty, downtime, consumables, powder efficiency, and employee training (learning curve). These factors significantly influence the actual cost of metal 3D printing.

Why Is the Machine Price Alone Not Meaningful?

A low purchase price can be misleading: high maintenance costs, production downtime, inefficient powder usage, or long learning curves can make the investment significantly more expensive in the long term.

How Does 2onelab Help Optimize Metal 3D Printer Costs?

With 2onelab, you benefit from high-quality printers (2Create & 2Create Plus) and matching equipment, as well as the expertise and experience of our team.

Efficient processes, targeted training, proper maintenance, and optimized material usage reduce metal 3D printing costs sustainably and make your production economical and reliable.

Further links:

Author: Markus Wolf

Passionate about 3D printing, while being

CTO and Co-Founder of 2onelab.